The Role of Magnetic Headsets in Bottling: Optimizing Your Capping Process

An efficient bottling and capping process is indispensable for food and beverage companies seeking to improve throughput and maintain high product quality. Within these processes, magnetic headsets significantly impact capping efficiency, torque control, and overall production performance. Magnetic headsets perform vital functions in both the bottling and capping phases of food and beverage production. By […]

The Importance of Preventive Maintenance for Beverage Capping Equipment

The beverage capping process is a critical stage in manufacturing and packaging, ensuring product freshness, quality, and safety. It is therefore essential that capping equipment, such as cap chucks and magnetic headsets, operate at peak efficiency and are free from mechanical issues. Many elements contribute to the success of efficient beverage manufacturing, but one factor […]

The Function and Importance of Cap Chucks in the Beverage Industry

Bottle cap chucks are the crucial interface between the capping machine and the bottle for a successful cap application. A quality designed and manufactured chuck is front line to a happy consumer. Since bottle caps vary in size, style, and shape depending on the product, capping chucks are available in a wide range of sizes, […]

Essential Repairs and Services for Food and Beverage Capping Equipment: Enhance Efficiency and Performance with JD Machinery

Ensuring the smooth operation of your capping equipment is crucial for maintaining production efficiency, product quality, and customer satisfaction, especially in the fast-paced beverage industry. Due to the wear and tear that these machines undergo during daily use, timely repairs and services become essential in maintaining optimal performance and avoiding costly downtime. With the right […]

Embracing Automation in the Food and Beverage Industry: How Magnetic Headsets Can Transform Your Production Line

As beverage manufacturers strive to remain competitive in an increasingly saturated market, the need for efficient, automated, and cost-effective production processes becomes ever more crucial. Automation advancements and innovative equipment, such as magnetic headsets, enable businesses to optimize their production lines, reduce downtime, and ensure consistent product quality. In this article, we will delve into […]

Unlocking the Potential of Retrofitting Capping Machinery for Enhanced Production Efficiency

In today’s ever-evolving beverage industry, companies are continuously seeking ways to optimize their production processes and minimize expenses. With capping machinery playing a pivotal role in ensuring product quality and safety, efficient and reliable capping equipment is of paramount significance. Retrofitting existing capping machinery can help companies maximize their assets’ potential and is often a […]

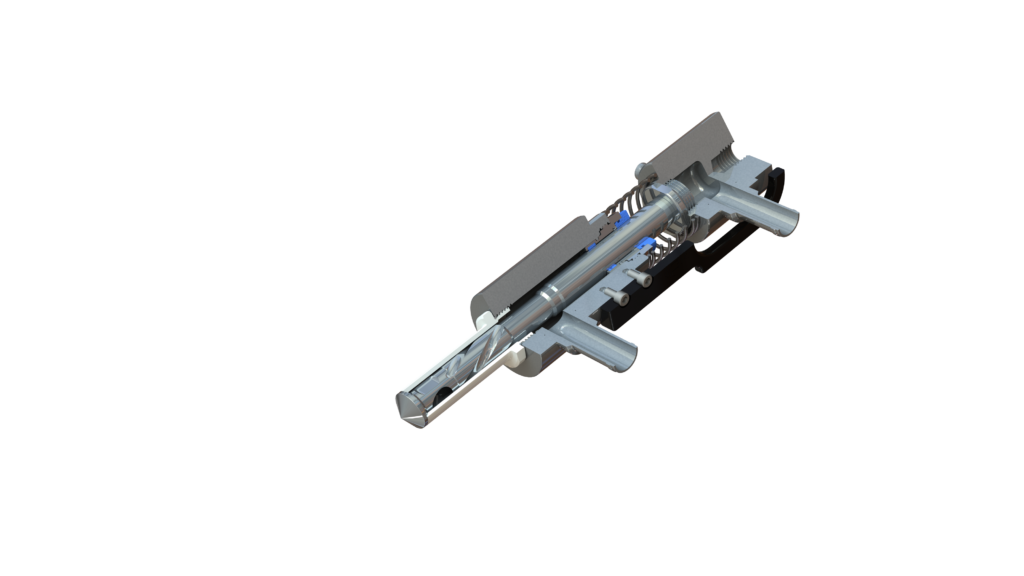

Magnetic Technologies and JD Machinery Sales and Service Introduce a NEW Pressure Gravity Filling Valve

JD Machinery is your exclusive distributor for the new Magnetic Technologies Pressure Gravity filling valve assembly. Myself and my service group have a combined 75 years of experience with pressure gravity fillers. This experience allows us to understand what makes a great filling valve and how to feed product to the machinery as well as […]

CAPPING MACHINES 3RD PARTY SUPPORT CAN HELP YOUR OPERATION

BENEFITS OF 3RD PARTY SUPPORT FOR CAPPING MACHINES SAVE MONEY This is a major opportunity to stretch the maintenance budget by reducing service support costs. Those extra funds can then be applied to those spare parts that are always in short supply. An experienced 3rd party maintenance technician can also bring to the table strong […]

MAGNETIC TECHNOLOGIES HYSTERESIS CAPPER CLUTCH VS RATCHETING CLUTCHES

This short video points out a little-known issue with a ratcheting capper clutch. They can under the right circumstances actually loosen the cap as they release the chuck from the closure. This can happen when the pulsating magnets are caught in just the wrong position. You can also clearly see the pulsating nature of the […]

THINGS TO CONSIDER WHEN LOOKING FOR A NEW BOTTLE CAPPING MACHINE

BOTTLE CAPPING MACHINE: 2019 BUYERS GUIDE The five key items when selecting the right bottle capping machine will be to define the closure, the package, the product, the filling temperature, and finally, the speed requirements in bottles per minute. The closure type helps to determine the capper requirements. Is the closure serrated vs smooth sided, […]