CAPPING MACHINES

Rotary Bottle Capping Equipment

A Capping Machine is used for the application of plastic and metal threaded caps as well as plastic snap caps, some fitments, and some types of corks and plugs. Quality cap application requires a well thought out machine that incorporates proper cam design and spindle speed control to facilitate application on closures with single lead or multi-lead threads as well as differing internal seals including the new plug seals for beverages. You also must consider application needs for standard serrated beverage caps to smooth side and dispensing type closures. Each requires a different approach in machine design. JD Machinery Sales and Service work with our clients to select a machine with the required features to meet their capping needs.

JD Machinery Sales and Service represents capping equipment capable of meeting our customer’s needs. Our Capping Machines are equipped with the latest technologies to achieve the highest speeds and very low defect rates. Our newest cappers are maintenance friendly with lubrication free spindles that provide a simple 2 bolt release mechanism. We have cappers available from 4 – 30 heads.

Applications for our Capping Machines include carbonated (sparkling water, energy drinks, soda), hot fill juice, water, and dairy. Our pick and place free-standing cappers include spindle speed control, custom enclosed cams, and quick-change spindles. All machines are available with HEPA filtration guarding.

Most importantly we offer highly experienced service support for installation, qualification, and training.

If you are looking at New or a Remanufactured option we can help. Contact us today for a quote or to discuss your needs.

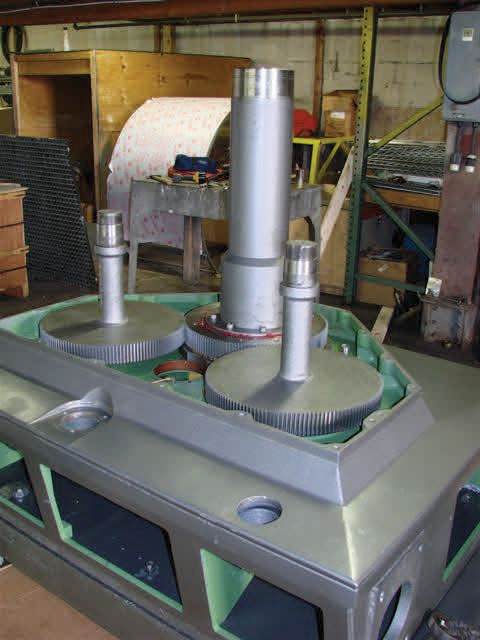

FREE STANDING ROTARY CAPPING MACHINE

Our Pick and Place capper offers customization with 4 to 30 heads. These are designed for both multi lead and single lead closures. Features include:

- Dual purpose head slides option for ROPP and screw caps

- Upside down cap rejection

- Bottle anti-rotation control

- Articulating chucks with corrosion resistant stainless steel construction

Our Free-Standing Rotary Capping Equipment is ideal for: aerosol, flip top, press-on, dispensing, long and short skirt ROPP, sport caps, over caps, and pre-threaded caps of all types. It can serve cap sizes up to 110 mm. The hysteresis bottle capping heads provide for repeatable and reliable cap application. The rotary capper offers high-speed production, which improves line efficiency while maintaining precision. Our Free-Standing Rotary Capping Equipment reduces product spillage and has features to keep products safe and sanitary.

ROPP CAPPER EQUIPMENT-New or Remanufactured

A perfect solution to your food, beverage, and distillery application. ROPP Capper is a Roll On Pilfer Proof capper designed to thread and seal aluminum caps onto ridged containers. ROPP Cappers are a specialized capping machine ideal for wine bottles, distilled spirits, olive oils, pharmaceutical products, or any other product that requires evidence that the container has been sealed and that no tampering has occurred.

We offer both new and remanufactured rotary ROPP capping equipment. Our remanufactured machines come with a full warranty and are available for a FAT prior to shipping. Quality ROPP heads are constructed of stainless steel and include a no cap no roll feature. Heads are available in all common sizes and for application on glass or plastic

We also offer custom-built machines for applying aluminum on aluminum

REBUILT CAPPER OPTIONS

We can also work with our Vendor to provide our clients rebuilt options for existing cappers including ROPP and screw caps. Full rebuilds are available for several OEM equipment options including Alcoa and Zalkin, through our vendor. All completed machine rebuilds would come with a 1 year warranty. Machinery guarding would be upgraded to industry standards and a production test for FAT is available.